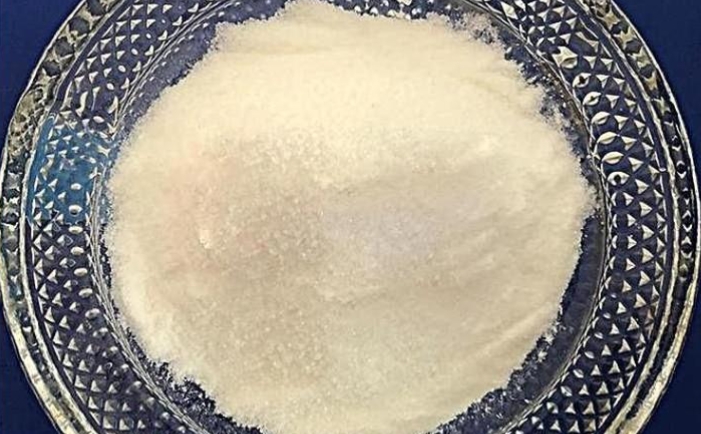

Cuprous chloride catalyst

As one of the commonly used copper-based catalysts in industry, cuprous chloride has the advantages of relatively stable catalytic activity, good selectivity and short reaction induction period. It is a catalyst that was widely used in industrial production in the early days. Many domestic laboratories are using this type of catalyst. However, cuprous chloride catalyst has poor chemical stability. It will absorb water and become damp during industrial storage, which will reduce the performance of the catalyst. The intermediates and by-products of the catalytic reaction of this catalyst will corrode the reaction device, thereby reducing the output. The silicon tetrachloride by-product produced during the reaction process is not easy to separate from M3, which increases the production cost. In addition, the selectivity of the product will decrease when the cuprous chloride catalyst is used. It is found that cuprous chloride can be reduced by silicon under heating conditions to produce metallic copper crystals. The generated copper crystals diffuse with silicon powder to produce highly active alloy contacts. At present, the research is mainly carried out from the aspects of morphology, production process and reaction mode with silicon powder. By preparing a highly loose flaky cuprous chloride catalyst, the content of M2 in the Rochow reaction can be significantly increased. Although a variety of methods have been used to improve the catalytic effect of catalysts, they are not suitable for industrial production. The complexity of the catalyst production process also leads to increased production costs. In the current large-scale production and huge investment in production raw materials, the industry still mainly uses low-cost, short-induction-period multi-component copper powder catalysts.

To learn more, click here

https://www.siliconematerial.net/